The transformation of sugar from a clear syrup to a rich, dark caramel is one of the most fascinating processes in the culinary world. It is a journey governed by precise temperature control, where each degree shift brings about a distinct change in color, flavor, and texture. This alchemical process, known as caramelization, is not merely a chemical reaction but an art form that has been perfected by confectioners and chefs over centuries. Understanding the temperature milestones is essential for anyone looking to master the creation of everything from delicate sugar work to deeply flavorful sauces and candies.

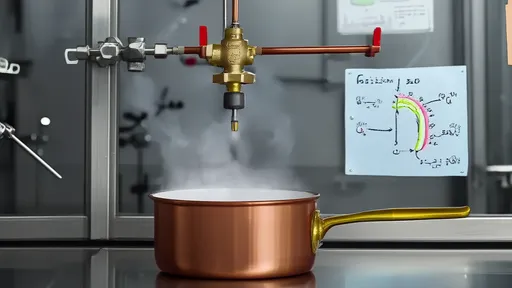

Caramelization begins when granulated sugar is heated, either dry or dissolved in water to form a syrup. As the temperature rises, the sugar molecules break down and recombine into new compounds, creating the complex flavors and aromas associated with caramel. The process is highly temperature-dependent, and even a few degrees can mean the difference between a light amber sauce and a bitter, burnt mess. For this reason, many professionals rely on a candy thermometer to achieve consistent results, though experienced hands often judge the stages by sight and sound.

The initial stage involves dissolving sugar in water over low heat to create a simple syrup. As the water evaporates and the temperature climbs past 212°F (100°C), the syrup becomes more concentrated. The first critical milestone is the thread stage, occurring between 230°F and 235°F (110°C to 112°C). At this point, the syrup forms fine threads when dropped from a spoon or between the fingers. It is often used for syrups and some icings but is not yet caramel.

As the temperature continues to rise, the syrup enters the soft-ball stage at around 235°F to 240°F (112°C to 116°C). When a small amount is dropped into cold water, it forms a soft, pliable ball. This stage is crucial for fudges and fondants. Following this is the firm-ball stage at 245°F to 250°F (118°C to 121°C), where the sugar forms a firmer ball that holds its shape but remains squeezable. Caramels and nougats typically target this range.

The hard-ball stage, from 250°F to 265°F (121°C to 129°C), produces a ball that is hard yet still pliable, ideal for marshmallows and rock candy. Next, the soft-crack stage at 270°F to 290°F (132°C to 143°C) results in strands that are firm but not brittle when cooled, used for taffy and butterscotch. The hard-crack stage follows at 300°F to 310°F (149°C to 154°C), where the sugar becomes brittle and glass-like, perfect for lollipops and brittle.

It is beyond the hard-crack stage that true caramelization begins. Around 320°F (160°C), the clear or pale yellow syrup starts to turn a light amber color. This is the point where the sugar molecules undergo profound chemical changes, producing rich, buttery flavors and a deep aroma. This light caramel stage is excellent for flans and crème brûlée, where a subtle caramel note is desired without bitterness.

As the temperature approaches 340°F (171°C), the caramel deepens to a medium amber, often referred to as the caramel stage. Here, the flavor becomes more intense and complex, with notes of toffee and nuts. This is the ideal range for caramel sauces, candies, and as a base for many desserts. The sugar is now fully caramelized, and any further heating will push it toward a darker, more robust profile.

Between 350°F and 360°F (177°C to 182°C), the caramel reaches a dark amber hue. At this stage, the flavors are bold and slightly smoky, with a hint of bitterness that can balance sweetness in recipes like dark caramel sauces or coatings. However, this is a critical window—the line between deep flavor and burnt sugar is thin. Precision is key, as exceeding 360°F (182°C) can quickly lead to a black, acrid mess that is unusable.

Several factors influence caramelization beyond temperature. The type of sugar used can affect the process; sucrose (table sugar) is most common, but fructose caramelizes at a lower temperature, while glucose may require higher heat. The presence of acids, such as lemon juice or cream of tartar, can invert the sugar, altering its behavior. Additionally, the method of heating—whether wet or dry—can change the rate and outcome. A wet caramel, made by melting sugar with water, offers more control and even heating, while a dry caramel, made by melting sugar alone, can develop flavors more quickly but risks uneven cooking.

Mastering caramel requires not only technical knowledge but also sensory awareness. The color change is the most obvious indicator, moving from light gold to deep mahogany. The aroma evolves from sweet to richly nutty, and finally to smoky. The sound of the syrup changes too, bubbling differently as water content decreases and sugar concentration increases. Many chefs learn to recognize the stages by these cues alone, developing an intuition that transcends thermometer readings.

In professional kitchens, caramel is used in myriad applications. It can be poured into molds to create delicate decorations, blended into sauces for desserts or savory dishes, or used as a coloring and flavoring agent in beverages and baked goods. Its versatility makes it a cornerstone of pastry arts. However, working with caramel demands caution. Molten sugar is extremely hot and can cause severe burns. It also continues to cook after removal from heat due to residual energy, so it must be cooled rapidly or adjusted with cream or butter to halt the process.

Despite the risks, the allure of caramel is undeniable. Its complex flavor profile, combining sweetness with depth and a touch of bitterness, elevates simple ingredients into extraordinary creations. From the clear syrup beginnings to the dark amber finish, each temperature point offers a new possibility, a new flavor, a new texture. This journey through heat is a testament to the transformative power of cooking, where science and art converge to create something truly magical.

For those embarking on their caramel-making journey, patience and practice are essential. Start with a reliable thermometer, but don’t hesitate to trust your eyes and nose. Experiment with different sugars and techniques, and take notes on what works and what doesn’t. Remember that even mistakes can be learning opportunities—though perhaps not edible ones. With time, you’ll develop the skill to navigate the stages of caramelization with confidence, unlocking a world of culinary potential that ranges from the subtly sweet to the profoundly complex.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025